Jan 26, 2026

Contact us today to discuss your requirements and discover how we can add value to your business.

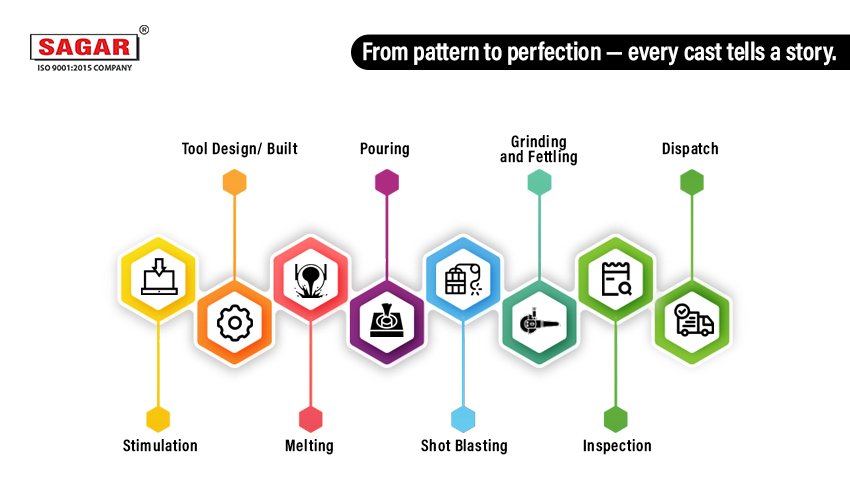

Casting is an ancient and adaptable manufacturing process and continues to be critical in creating anything from complex machine parts to massive industrial components. Here at Sagar Foundry, we have improved the casting process with precision, creativity, and commitment to quality to ensure that every casting meets or exceeds standard requirements. We are excited to take you through the entire journey of from pattern to final delivery, highlighting how raw materials become reliable castings.

The process starts with the pattern design process. A perfect copy of the final product is called a pattern. Experienced pattern makers can use materials such as wood, metal, or plastic to create patterns. At Sagar Foundry we will consult with our clients to ensure that the pattern provided meets the dimensional requirements, while also promoting efficiency and reducing production costs.

Once the pattern is as desired, it is put into the moulding box and sand (with binders) is compacted around the pattern to create the mould cavity. This procedure shows the casting’s external dimensions. If there are intricate features, cores can be used to generate internal cavities. Sagar Foundry will combine the craft of traditional moulding techniques with current moulding equipment and processes to achieve accurate and repeatable moulds for production.

The metal selected, typically cast iron or ductile iron or an alloy, is melted in a furnace at exact temperatures. We have good metallurgical controls in place so that the chemical make up of the molten metal can meet the specifications. At this point, the raw material undergoes a fundamental transformation.

When molten, the metal is poured into the prepped mould. Timing, temperature, and technique is of utmost importance here. Modest adjustments to any one of these variables can have an impact on the final result. The pouring operations at Sagar Foundry is undertaken by trained professionals who follow strict safety procedures and ensure the fill is smooth and without any defects.

The heated liquid metal solidifies in the mold’s shape as it cools. The cooling rate affects the properties and grain structure of the metal. Sagar Foundry manages this step in the process to prevent stresses, cracks or deformations and it will provide the best mechanical performance.

The solidified casting is removed from the mold after it has completely cooled. This process is called shakeout, and the approximate form of the product is revealed for the first time. At Sagar Foundry, we utilize automated shakeout systems to ensure an efficient process while protecting the integrity of the casting.

The casting is cleaned to remove sand, flash, and residue. A casting may be ground, blasted, or other surface treatments will be done to achieve a flat surface. At Sagar Foundry we have put additional focus on fettling. A casting that is well finished not only looks better but will perform better.

Before leaving the foundry, each casting passes through a meticulous quality inspection. Many aspects of the casting are inspected, including dimensional accuracy, mechanical properties, and surface quality, using the latest testing equipment. Quality is at the helm of every single aspect of Sagar Foundry’s operations, and everything we produce must meet the customer’s high standards.

Some castings require machining to meet tighter tolerances or specific features. Once machined, the product is ready for assembly or direct use. Sagar Foundry can quickly provide inhouse machining so you can go from casting to final product seamlessly.

With decades of experience, Sagar Foundry produces castings that are accurate, reliable, and long lasting by combining traditional craftsmanship with contemporary technologies. Our fully integrated Industrial foundry is capable of producing the simplest piece, or the most complex industrial component with quality built in at every phase for performance that lasts for generations.